GRP Grating Panels

Why GRP Grating Panels Are Replacing Steel and Timber in High-Traffic Environments

When large numbers of people or vehicles are involved, surface safety, structural integrity, and ease of installation become critical. Whether you’re managing a festival site, building a rooftop car park, or maintaining industrial walkways, the traditional use of steel or timber for ground-level and elevated flooring is increasingly being phased out in favour of GRP grating panels.

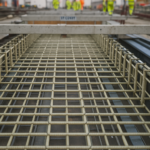

Glass Reinforced Plastic (GRP) grating panels provide a lightweight yet load-bearing alternative to metal grilles and wooden boards. With integrated anti-slip properties and corrosion resistance, they offer a long-term, zero-maintenance solution that works across demanding outdoor and indoor environments.

At Engineered Composites, we supply GRP grating panels that meet BS EN 13706 specifications for structural pultrusion and are available in open mesh, mini mesh, and solid top variants depending on site requirements.

Technical Performance of GRP Grating Panels

Unlike steel, which can corrode, or timber, which warps and rots, GRP grating panels are made using continuous fibreglass strands embedded in a thermosetting resin matrix. This delivers outstanding mechanical and chemical resistance.

Core performance specifications for our GRP grating panels:

- Load capacity: Up to 5kN/m² for pedestrian use or higher with structural framing

- Ultimate tensile strength: Up to 240 MPa

- Slip resistance: Anti-slip grit exceeds BS 7976 Part 2 standards

- Fire rating: Class 2 under BS 476 Pt 7

- Resin types: Isophthalic or vinyl ester for chemical resistance

- Open area: Available in 38 x 38 mm open mesh or 20 x 20 mm mini mesh

- UV stability: Colour-fast and sunlight resistant for long-term outdoor use

This combination of strength and resilience makes GRP grating panels suitable for pedestrian footbridges, roof decks, raised flooring systems, and temporary installations.

Where GRP Grating Panels Deliver Maximum Impact

- Music festivals and events: Rapid-deploy panels to protect turf and support crowds

- Multistorey car parks: Anti-slip, drainage-friendly surfaces that reduce corrosion risk

- Pedestrian bridges: Lightweight and corrosion-free decking over roads or water

- Rooftop access: Non-conductive and UV-stable platforms for maintenance staff

- Wastewater treatment plants: Resistant to chemical exposure and slip hazards

- Chemical and utility sites: Ideal for bunds, trench covers, and platforms

Because GRP grating panels can be cut to size on-site without hot works, they’re fast to install and easy to adapt to layout changes.

Case Study: GRP Grating Panels for Festival Infrastructure

A large UK-based outdoor festival faced issues with traditional timber panels that became dangerously slippery in rain and required daily maintenance. The events team selected open mesh GRP grating panels from Engineered Composites for their temporary walkways, equipment zones, and backstage structures.

The panels were laid quickly across uneven ground, provided high visibility and grip even during heavy downpours, and were lifted and reused across multiple festivals. Staff reported a 75% reduction in slip incidents compared to the previous year, and maintenance teams noted zero warping or delamination after full-season use.

This project reinforced GRP’s value in fast-paced, temporary environments where safety and speed are non-negotiable.

Sustainable, Low-Cost, High-Spec Solution

GRP grating panels are not just high performance — they’re also a cost-effective and environmentally preferable solution. Their low weight reduces transport emissions, while the long service life and minimal maintenance requirements drastically cut lifecycle costs. Unlike steel, there’s no need for galvanising or repainting. Unlike wood, there’s no need for preservatives or sealing.

Our GRP grating panels contribute to BREEAM and LEED schemes and can be supplied with Environmental Product Declarations (EPDs) upon request.

Common Questions About GRP Grating Panels

GRP grating panels outperform steel and timber in key areas such as durability, weight, and maintenance. Unlike steel, GRP will not rust, and unlike timber, it won’t warp, rot, or require chemical treatments. These panels are lightweight yet load-bearing, making them easy to install without heavy equipment. They’re also resistant to UV rays, chemicals, and fire, offering long-term performance with minimal upkeep. With anti-slip surfaces that exceed BS 7976 standards, GRP grating panels are safer for pedestrians in high-traffic zones, indoors or outdoors, and provide a lower-cost alternative across their lifecycle.

GRP grating panels are highly versatile and used in various high-traffic and high-risk environments. Common applications include pedestrian footbridges, rooftop access platforms, multistorey car parks, and music festivals. Industrial sectors such as wastewater treatment, chemical processing, and utility services also favour GRP for trench covers, bunds, and walkways. Their non-conductive and corrosion-resistant qualities make them ideal for electrically sensitive or chemically harsh areas. These panels are also popular for temporary installations due to their fast, hot-work-free installation and easy on-site modification, making them a go-to solution for projects that require safety, speed, and adaptability.

Yes, GRP grating panels are engineered for long-term outdoor performance. Their UV-stable resin systems prevent colour fading and degradation from sunlight, while their anti-slip grit ensures consistent traction in wet or icy conditions. Unlike steel, they won’t corrode in rain or sea spray, and unlike timber, they won’t rot or swell when exposed to moisture. This makes them ideal for roof decks, car parks, and pedestrian bridges. Additionally, GRP’s non-conductive nature adds an extra layer of safety near electrical installations. These weather-resistant properties help extend the life of infrastructure and reduce maintenance demands.

Absolutely. One of the major advantages of GRP grating panels is their ease of customisation during installation. They can be cut to size using standard hand tools without generating sparks or requiring hot works permits. This makes them safer and more efficient to install in sensitive or remote environments. Their modular design also means they can be adapted quickly to layout changes, making them ideal for projects that demand flexibility, such as event setups, utility site access, or retrofit flooring. This onsite adaptability reduces installation time and labour costs significantly.

Yes, GRP grating panels from reputable suppliers like Engineered Composites meet key British and European standards. Structural pultrusion complies with BS EN 13706, while anti-slip performance meets BS 7976 Part 2. Fire safety is addressed with a Class 2 fire rating under BS 476 Pt 7. Additionally, different resin systems such as isophthalic or vinyl ester ensure chemical resistance suited to the application. These certifications demonstrate GRP’s readiness for use in safety-critical sectors, including transport, utilities, and construction, providing peace of mind for specifiers and contractors managing high-risk, high-traffic environments.

Yes, GRP grating panels offer sustainability and economic benefits. Their lightweight construction reduces transport emissions, while their durability ensures decades of use without replacement. They require no painting, sealing, or rust prevention, lowering ongoing maintenance costs. Over time, this results in a significantly lower total cost of ownership compared to steel or timber. GRP panels also contribute to BREEAM and LEED sustainability credits, and Environmental Product Declarations (EPDs) are available upon request. For projects aiming to balance performance, safety, and environmental responsibility, GRP grating panels are a smart long-term investment.

Conclusion: Upgrade to GRP Grating Panels

Whether you’re managing a car park deck, specifying walkways for a processing site, or building temporary access flooring for a major event, GRP grating panels offer a reliable, proven alternative to traditional materials.

Lightweight, corrosion-resistant, slip-proof and long-lasting, they provide a future-ready flooring system for both permanent and temporary infrastructure.

Want to Learn More or Get a Quote?

Speak to Engineered Composites to discuss GRP grating panels for your next project, and benefit from compliant, cost-effective, and sustainable solutions trusted across the UK.