Grated Flooring: Technical Insights, Material Options, and Industry Applications

Introduction: The Importance of Grated Flooring in Modern Infrastructure

Grated flooring is a critical component in industrial, commercial, and public infrastructure, providing a safe, durable, and functional walking surface that can withstand heavy loads, allow drainage, and offer slip resistance in demanding environments. Whether used in factories, rail stations, offshore platforms, or public walkways, grated flooring is designed to maintain performance and safety even under constant exposure to foot traffic, weather, chemicals, or heavy equipment.

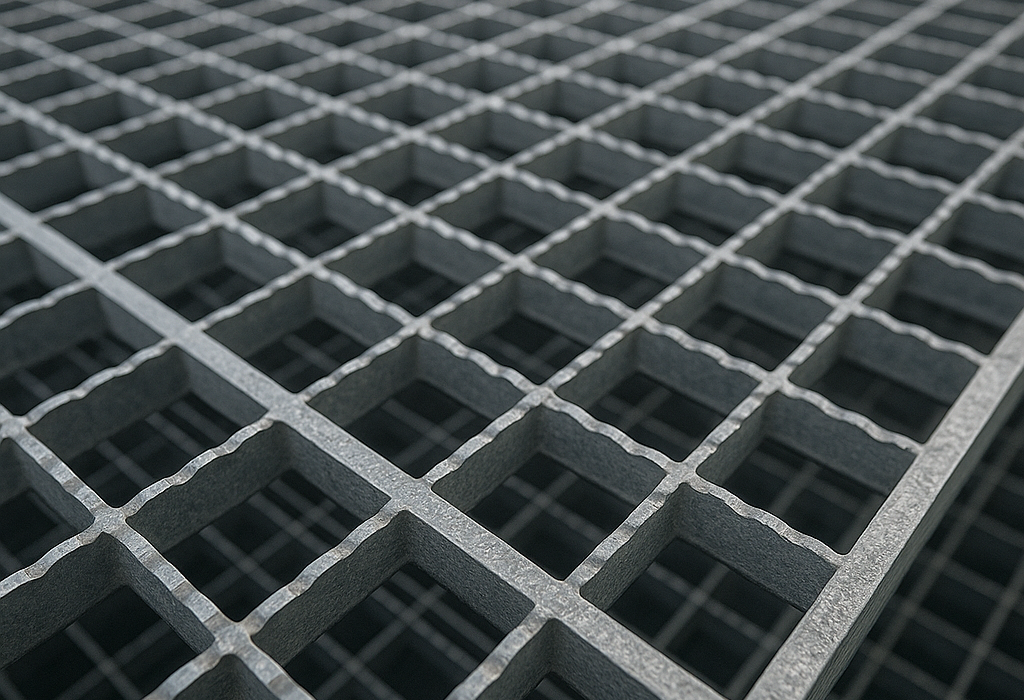

In its most basic form, grated flooring consists of a load-bearing grid or mesh structure that supports loads while allowing fluids, debris, and air to pass through. This makes it a versatile choice for environments where drainage, ventilation, or spill containment is important. Traditional materials include steel, aluminium, timber, and concrete, but advances in composite manufacturing have made Glass Reinforced Plastic (GRP) grated flooring a leading choice for many sectors.

Engineered Composites supplies grated flooring in a variety of designs and materials to meet diverse project requirements. The company’s GRP grated flooring range offers unmatched corrosion resistance, slip resistance, and weight-to-strength performance, making it suitable for the harshest operating environments.

Grated Flooring Materials: An Overview

Grated flooring is manufactured in several material types, each with unique strengths and limitations. Selecting the right material requires an understanding of mechanical performance, environmental resistance, compliance with safety standards, and life-cycle costs.

Steel grated flooring has been the traditional choice for heavy-duty industrial environments. It offers high load-bearing capacity and impact resistance but is prone to corrosion without galvanising or painting. Maintenance requirements can be significant in marine or chemical environments.

Aluminium grated flooring is lighter than steel and naturally corrosion-resistant in many settings. However, it has a lower modulus of elasticity, which means greater deflection under load, and it can be prone to surface wear in high-traffic areas.

Timber grated flooring is less common in modern infrastructure but is sometimes used for decorative or low-load applications. It has limited durability in wet or chemical environments and requires regular treatment to prevent decay.

Concrete grated flooring is typically precast and used in specialised civil engineering applications. While durable under compression, it is heavy, inflexible, and susceptible to chemical attack.

GRP grated flooring, available from Engineered Composites, combines the strength of glass fibre with the durability of a thermosetting resin. This produces a lightweight yet high-strength product that resists corrosion, chemical attack, and weathering without the need for ongoing protective coatings. It also offers inherent slip resistance and electrical insulation, making it particularly valuable in safety-critical environments.

Technical Performance of GRP Grated Flooring

The performance of GRP grated flooring is determined by its fibre content, resin type, manufacturing process, and surface treatment. High-quality products, manufactured to BS EN 13706 and BS EN 4592, exhibit mechanical and safety characteristics that make them suitable for demanding industrial use.

Open mesh GRP grated flooring is produced using a moulded process, resulting in a one-piece construction with continuous glass fibres in both directions. This ensures high strength and excellent impact resistance. Load-bearing capacity can exceed 7.5 kN/m² for standard industrial panels, with deflection well within acceptable safety limits.

Slip resistance is a key safety feature. GRP grated flooring from Engineered Composites is manufactured with an integrated quartz grit surface, which consistently achieves low slip potential ratings under BS 7976 testing in both wet and dry conditions. This makes it ideal for external walkways, offshore platforms, and areas prone to spills.

Chemical resistance is another significant advantage. GRP grated flooring can withstand acids, alkalis, solvents, and saltwater, making it suitable for marine, wastewater, and chemical plant environments. Vinyl ester resin formulations further enhance resistance in aggressive chemical applications.

GRP is also non-conductive and non-magnetic, ensuring safety in high-voltage environments and compatibility with sensitive electronic equipment. Its low thermal conductivity (<0.3 W/mK) reduces temperature transfer, improving comfort and safety in certain installations.

Types of Grated Flooring

Grated flooring is available in different designs and configurations to suit varying operational needs.

- Open mesh grated flooring allows maximum drainage and ventilation while providing a safe walking surface. This is the most common type for industrial and marine environments.

- Mini mesh grated flooring offers a smaller aperture, which prevents objects from falling through and improves comfort for pedestrian traffic, including high heels or mobility aids. It is often used in public walkways and access platforms.

- Solid top grated flooring provides a continuous walking surface with the strength benefits of a grating structure beneath. This is useful for areas where spills must be contained or where debris needs to be kept from falling below.

- Stair treads and landing platforms are manufactured using the same grated flooring materials and designs, ensuring continuity in safety and performance.

Each of these grated flooring types is available in steel, aluminium, or GRP. However, for applications where corrosion resistance, slip resistance, and low maintenance are priorities, GRP grated flooring offers clear advantages.

Applications of Grated Flooring Across Industries

Industrial facilities use grated flooring extensively for walkways, mezzanines, and maintenance platforms. GRP grated flooring provides safety and durability in areas exposed to chemicals, oils, or wet conditions, without the corrosion issues associated with metal.

Marine and offshore environments demand materials that can withstand saltwater and harsh weather. GRP grated flooring maintains structural integrity and slip resistance in these challenging conditions, making it a standard choice for jetties, pontoons, and oil rigs.

Railway infrastructure uses grated flooring for trackside walkways, platform extensions, and access points. The non-conductive nature of GRP grated flooring is particularly important in electrified rail networks, where electrical insulation enhances worker safety.

Water treatment and utility plants require flooring that resists chemical attack and provides secure footing. GRP grated flooring meets these needs while reducing maintenance costs.

Public infrastructure such as bridges, pedestrian walkways, and viewing platforms benefits from the slip resistance and low maintenance of GRP grated flooring, especially in outdoor settings.

Data centres utilise non-conductive grated flooring in maintenance areas and rooftop plant access, reducing electrical hazards and ensuring compliance with safety standards.

Compliance and Safety Standards

Grated flooring products must comply with relevant standards to ensure performance and safety. BS EN 13706 governs pultruded profiles, BS EN 4592 covers industrial flooring and stair treads, and BS 7976 sets slip resistance testing methods.

Fire performance is addressed through BS 476 Part 7 and ASTM E84, with GRP grated flooring from Engineered Composites available in Class 2 fire retardant formulations.

For environments requiring environmental certification, GRP grated flooring can contribute to BREEAM and LEED credits due to its long service life, low maintenance needs, and reduced embodied carbon.

Sustainability and Whole-Life Costs

Sustainability is increasingly influencing material selection. GRP grated flooring is lightweight, reducing transportation emissions, and requires no protective coatings during its life cycle. This eliminates the environmental impact of repeated painting or galvanising associated with steel.

With a service life exceeding 50 years in many applications, GRP grated flooring offers significant whole-life cost savings compared to metals or timber. Its corrosion resistance reduces unplanned downtime and maintenance costs, improving asset reliability and operational safety.

Installation and Maintenance

GRP grated flooring is straightforward to install, with panels that can be cut on site using standard tools. Fixings are designed for secure attachment to steel, concrete, or GRP substructures. The light weight of GRP panels reduces manual handling risks and often eliminates the need for heavy lifting equipment.

Maintenance requirements are minimal. Periodic cleaning is usually sufficient to maintain performance and appearance. Unlike steel or timber, GRP grated flooring does not require repainting, galvanising, or chemical treatment.

Case Studies

In a coastal marina project, GRP grated flooring was installed on pontoons to replace corroded steel panels. The new flooring provided immediate improvements in slip resistance and eliminated the need for regular repainting, saving maintenance costs over time.

A wastewater treatment facility replaced aluminium flooring with GRP grated flooring to improve chemical resistance and worker safety. The quartz grit surface reduced slips, while the vinyl ester resin formulation resisted aggressive cleaning chemicals.

On a rail infrastructure project, Network Rail specified GRP grated flooring for trackside maintenance walkways. The non-conductive nature of the flooring improved electrical safety in electrified zones, while its corrosion resistance ensured longevity without costly maintenance.

Conclusion

Grated flooring plays a vital role in ensuring safe, durable, and functional access in industrial, marine, transport, and public environments. While traditional materials like steel, aluminium, timber, and concrete each have their uses, GRP grated flooring offers a combination of corrosion resistance, slip resistance, low maintenance, and compliance with strict safety standards that make it the optimal choice for many applications.

By selecting the right material and ensuring compliance with relevant BSI and ISO standards, engineers and specifiers can deliver grated flooring systems that provide decades of safe, reliable service while meeting sustainability goals.