GRP Rebar

Corrosion-resistant, lightweight and high-strength composite rebar for concrete reinforcement in marine, chemical and civil engineering applications.

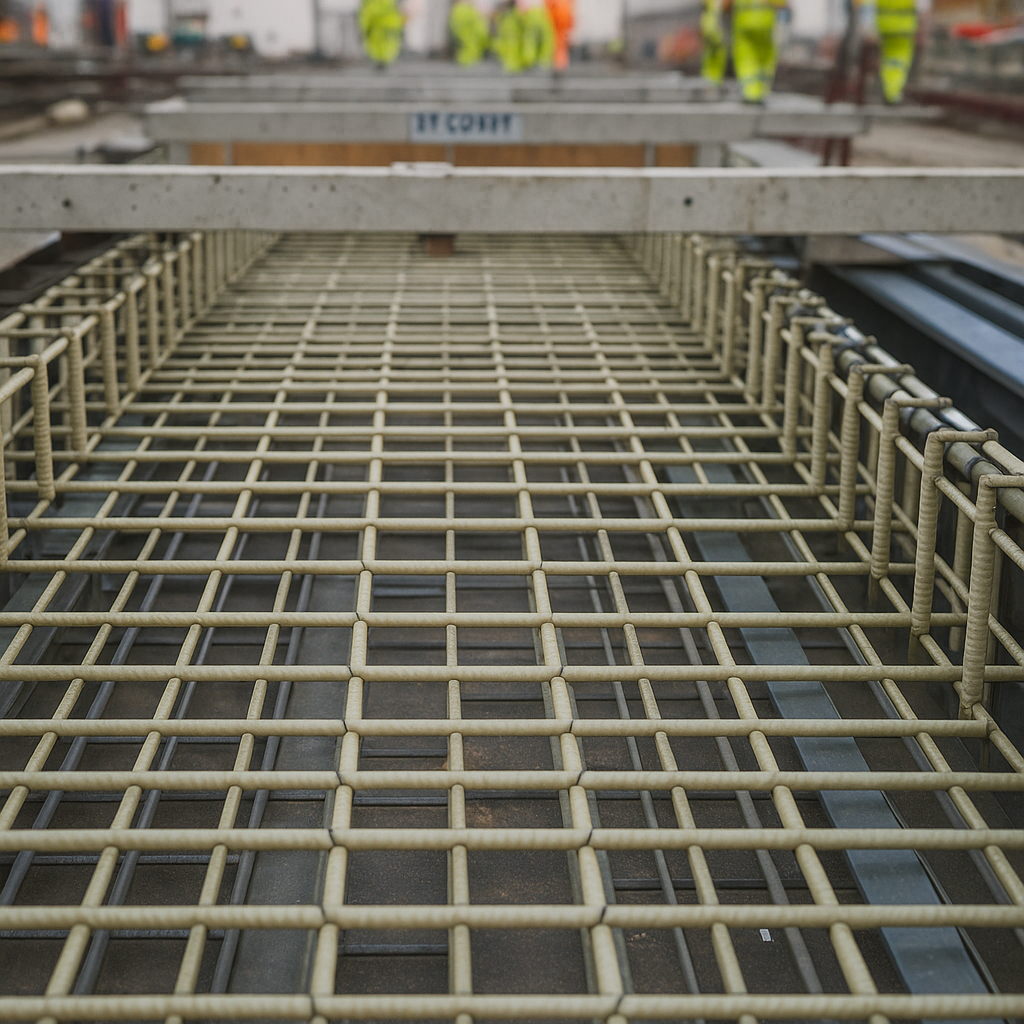

Engineered Composites GRP Rebar, also known as FRP (Fibre Reinforced Polymer) rebar, is a high-performance alternative to steel for reinforced concrete structures. Manufactured using pultruded glass fibres and resin, GRP rebar provides exceptional durability in harsh environments where steel would corrode or degrade.

It is non-metallic, non-magnetic and lightweight, making it easy to handle, cut and install with no risk of rust, conductivity or long-term corrosion.

GRP Rebar

Our GRP Rebar Solutions

Explore our specialist GRP Rebar product range designed for high-performance reinforcement in demanding structural and corrosive environments.

- Specifications

Our GRP Rebar products are precision-engineered to meet the rigorous demands of modern infrastructure projects.

Tensile Strength: 483–1600 MPa depending on grade

Elastic Modulus: ~50,000 N/mm²

Bending Strength: ~400 N/mm²

Shear Strength: ~460 N/mm²

Diameter Range: 6mm to 32mm

Available Lengths: Available in 5m Lengths

Weight Advantage: ~70% lighter than steel

Finish: Sanded for improved adhesion

- Technical Standard

Engineered Composites’ GRP Rebar complies with all relevant mechanical and safety benchmarks for reinforced structures in transportation, utility, and civil sectors.

Corrosion Resistance: Impervious to rust and decay in wet conditions

Non-Conductive: Safe near electrical systems and cable ducts

Non-Magnetic: No electromagnetic interference

Fire Safe: GRP inherently resists ignition and meets fire compliance standards

Compressive Strength: Supports structural integrity in load-bearing concrete

Compliant Use: Proven performance in HS2 tunnel wall pillars and rail infrastructure

Corrosion & Weather Resistant

No rust, rot, or degradation over time

Non-Conductive & Fire Retardant

Safe for electrical and industrial sites

Lightweight & High Strength

Easy to install with exceptional durability

Why Choose GRP Rebar?

Our GRP Rebar is engineered for strength, longevity, and corrosion resistance. It performs reliably in demanding environments without the weight, conductivity, or corrosion issues of traditional steel.

Corrosion Resistant

Will not rust, rot, or degrade in harsh or chemical environments.

Lightweight & Easy to Install

Easier to transport and handle on-site, reducing installation time and labour.

Non-Conductive & Safe

Ideal for use around electrical systems, improving onsite safety.

Durable & Long-Lasting

High strength-to-weight ratio with excellent fatigue resistance.

Low Maintenance

No need for protective coatings or ongoing treatment.

Need Help Specifying GRP Rebar?

Let our team help you choose the right diameter, finish and layout for your project. We offer expert support and fast delivery across the UK.

Applications of GRP Rebar

GRP Rebar is increasingly specified in construction projects that require corrosion resistance, non-conductivity, or reduced weight. Below are common applications categorised by environmental and technical requirements.

Structures Exposed to De-Icing Salts

GRP Rebar is ideal for structures that endure regular exposure to de-icing salts, which typically cause corrosion in steel reinforcement.

Structures Built In or Close to Sea Water

Marine environments demand corrosion-resistant solutions. GRP Rebar offers excellent durability for coastal and submerged installations.

Structures Subject to Other Corrosive Agents

In industrial settings with high chemical exposure, GRP Rebar ensures long-term durability without the need for extensive maintenance.

Structures Requiring Low Electrical Conductivity / Electromagnetic Neutrality

GRP Rebar’s non-metallic, non-magnetic properties make it suitable for environments where electromagnetic interference or conductivity poses safety risks.

Temporary Concrete Structures in Tunnelling Applications

GRP Rebar can be used in tunnel linings and mining walls that are later excavated or demolished, thanks to its compatibility with mechanised boring and low removal resistance.

Weight-Sensitive Structures

In areas with poor load-bearing soil, remote access, or seismic sensitivity, the lightweight properties of GRP Rebar reduce structural load and logistics costs.

Thermally Sensitive Applications

GRP Rebar is compatible with thermally insulated concrete and prevents thermal bridging. It’s suitable for environments that require controlled heat retention.

Environmental Considerations

GRP Rebar has a lower through-life environmental impact than steel rebar.

Applications of GRP Rebar

GRP Rebar is ideal for structures that endure regular exposure to de-icing salts, which typically cause corrosion in steel reinforcement.

Examples include:

Bridge decks

Car parks

Elevated roadways

Marine environments demand corrosion-resistant solutions. GRP Rebar offers excellent durability for coastal and submerged installations.

Examples include:

Caissons

Dry docks

Jetties, piers, and quays

Offshore platforms

Sea defences and walls

In industrial settings with high chemical exposure, GRP Rebar ensures long-term durability without the need for extensive maintenance.

Examples include:

Chimneys

Petrochemical plants

Paper/pulp mills

Nuclear power stations

Wastewater treatment plants

GRP Rebar’s non-metallic, non-magnetic properties make it suitable for environments where electromagnetic interference or conductivity poses safety risks.

Examples include:

Airport control towers

Aluminium/copper smelting plants

Telecoms and transmission tower bases

Railway crossings

Toll road sensor arrays and booths

MRI suites in hospitals

GRP Rebar can be used in tunnel linings and mining walls that are later excavated or demolished, thanks to its compatibility with mechanised boring and low removal resistance.

Examples include:

Mining walls

Underground rapid transport structures

Vertical access shafts

In areas with poor load-bearing soil, remote access, or seismic sensitivity, the lightweight properties of GRP Rebar reduce structural load and logistics costs.

Examples include:

Remote location infrastructure

Foundations in soft soil

Earthquake-prone regions

GRP Rebar is compatible with thermally insulated concrete and prevents thermal bridging. It’s suitable for environments that require controlled heat retention.

Examples include:

Thermally insulated housing

Heated basements and floors

GRP Rebar has a lower through-life environmental impact than steel rebar:

Lower energy use in production

Lighter weight = reduced transport emissions

Smaller required concrete cover means less cement

Extended lifespan due to corrosion resistance

Less maintenance chemicals used

Easier demolition and recycling with concrete aggregate

Discover More About GRP Rebar

-

Brochure & Tech Specs

View our full specifications instantly! Download Brochure

-

See It in Action

Explore real-world applications! View Case Studies

-

Have Questions? Let's Talk!

Get expert advice today.

Contact Us

What Clients Say About Our Company

EXCELLENTTrustindex verifies that the original source of the review is Google. The firm and staff were all excellent, the product was very well finished and all the advice given was very helpful, unfortunately it turned out to be of no use for my application, but this in no way reflects on the company that made an excellent product, I wanted a long tube to put an aerial inside it, fibreglass is normally transparent to radio signals, but something in the make up of the fibreglass tube was totally blocking the radio signals from getting out of the tube, the problem is possibly to do with the colouring agent, the tube I had was grey, darker colours can often cause problems for aerials, possibly if I'd chosen yellow, the other colour offered by the firm it may have worked well, but all this is my problem, not the company that made the tube, the tube is Very well made and nicely finished off, the staff could not have been more helpful, despite my problems this is a Highly Recommended firm. Pete.Posted onTrustindex verifies that the original source of the review is Google. Fantastic company to deal with, they always respond really quickly, have incredibly fast despatch times and provide consistently high quality, innovative GRP products. As a company, we couldn’t ask for more, thanks Engineered Composites.Posted onTrustindex verifies that the original source of the review is Google. Excellent Customer Service. Supplied Composite rebar for our precast units (Macrete Ireland Ltd)Posted onTrustindex verifies that the original source of the review is Google. We've being using Engineered Composites services for over 10 years & long may it continue. Professional at all times & no issues with quality or prices. Great range & availability, would highly recommend them.Posted onTrustindex verifies that the original source of the review is Google. 5-Star service, great company to work with. Make's my life easier with prompt response times, on schedule deliveries and effective communication throughout.Posted onTrustindex verifies that the original source of the review is Google. This is an extremely professional company at the forefront of GRP Composite technology. Always willing to supply First Class advice and bespoke GRP solutions. Highly Recommended

GRP Rebar FAQs

GRP Rebar, also known as Glass Reinforced Plastic Rebar, is a non-metallic alternative to traditional steel reinforcement. Unlike steel, GRP rebar is corrosion-resistant, non-conductive, and lightweight. It’s made from continuous glass fibres and thermosetting resin, making it ideal for construction in harsh environments where steel would rust or degrade. GRP rebar also reduces maintenance costs over the long term.

GRP rebar is commonly used in marine environments, bridge decks, retaining walls, foundations, tunnels, and chemical plants. Thanks to its resistance to corrosion, it’s the preferred choice for infrastructure exposed to saltwater, moisture, or harsh chemicals. It’s also ideal for use in non-magnetic or electrically sensitive areas where traditional steel reinforcement could cause interference or pose safety risks.

Yes, GRP rebar supplied by Engineered Composites meets key UK and international standards including BS EN ISO 13706 and ASTM D7957. These standards ensure mechanical strength, chemical resistance, and fire performance, making it suitable for public infrastructure and commercial projects. It also aligns with HS2 and Network Rail specifications, offering reliable compliance for safety-critical applications.

GRP rebar typically lasts much longer than steel in corrosive environments. With a projected lifespan exceeding 100 years under normal service conditions, it resists degradation from water, salt, chemicals, and UV exposure. Unlike steel, GRP does not require coatings or treatments to maintain performance, offering long-term durability and reduced lifecycle costs.

Absolutely. GRP rebar has a high tensile strength-to-weight ratio, making it suitable for many structural and load-bearing applications. It can outperform steel in specific conditions, especially where corrosion is a concern. While it has a lower modulus of elasticity, engineers can compensate by adjusting design specs. It’s widely used in foundations, precast concrete, and infrastructure projects.

Yes, GRP rebar is a sustainable choice. It reduces environmental impact by eliminating the need for rust-proof coatings and frequent maintenance. Its long lifespan and corrosion resistance mean fewer replacements and repairs, which lowers resource consumption. Plus, its lightweight nature reduces transport emissions, making GRP rebar a greener option for eco-conscious construction projects.

Choosing the right GRP rebar depends on your project’s exposure to moisture, chemicals, electrical interference, and load demands. At Engineered Composites, we offer a range of GRP rebar sizes, surface finishes, and specifications, including sand-coated or epoxy resin options. Speak with our technical team to ensure the optimal product selection based on BS, ASTM, or project-specific standards.