GRP Flooring

GRP Flooring Systems for Safer, Smarter Industrial Spaces

Engineered Composites supplies GRP flooring solutions designed for strength, safety, and speed of installation — the smarter choice for modern industrial, marine, and infrastructure projects.

Engineered Composites provides high-performance GRP flooring systems that deliver proven strength, reliability and long-term safety in demanding environments. Manufactured using precision pultruded profiles, our flooring combines lightweight construction with exceptional load capacity and slip resistance, creating a safe and cost-effective alternative to steel or timber floors.

Available from UK stock for rapid delivery, each GRP flooring panel is corrosion-resistant, non-conductive and fully compliant with BS EN 13706 and BS 4592 standards. Installation is simple and fast, helping contractors reduce labour time and avoid costly maintenance in the future.

Whether used for industrial walkways, platforms, or marine decks, GRP flooring from Engineered Composites offers a lasting solution that performs where traditional materials fail — keeping your project compliant, efficient and safe for years to come.

Trusted GRP Flooring Systems

Engineered Composites supplies GRP flooring systems that save time on site and reduce long term maintenance costs. Each panel is corrosion resistant, non conductive and built to perform for decades without repainting or surface treatment. Once installed, it delivers reliable slip resistance and strength with zero upkeep required.

We hold extensive UK stock ready for fast nationwide delivery, helping contractors meet tight schedules and avoid costly delays. Panels can be supplied cut to size or in modular form for rapid installation. Designed for efficiency and durability, GRP flooring from Engineered Composites keeps projects moving while lowering lifetime costs.

-

Product Specifications

Our GRP Flooring has been independently tested and complies with BS 7976 for slip resistance and ASTM E84 Class 2 for fire safety. It also meets the requirements of BS 4592-4 for industrial flooring and BS EN ISO 14122-2 for safe access to machinery.

Standard Panel Size: 6m × 500mm (custom sizes on request)

Panel Thickness: 40mm standard (other options available)

Load Capacity: Up to 5 kN/m² depending on span

Weight: Approximately 12–15 kg/m²

Surface Finish: Quartz gritted anti slip R13 rated

Temperature Range: -40°C to +120°C

Fire Rating: ASTM E84 Class 2 / BS 476 Part 7 Class 2

Colours: Standard grey, custom RAL colours available

-

Technical Standards and Performance

Engineered Composites’ GRP flooring systems are designed to meet all relevant UK and European standards for performance, safety and reliability. Manufactured under ISO 9001 quality management, each panel offers consistent strength, precision and surface quality.

Key Features:

Independently tested to BS and EN standards.

Fire retardant and non conductive construction.

Anti slip, corrosion and chemical resistant surface.

UV and weather stable for long term external use.

Manufactured using high grade pultruded GRP profiles.

Designed for industrial, marine, and public access environments.

Anti-Slip GRP Flooring Sheets

| Cover Width (w) mm | Height (h) mm | Thickness (t) mm | Weight kg/m | Colour |

|---|---|---|---|---|

| 500 | 40 | 4.50 | 8.70 | Grey |

| Cover Width (w) mm | Height (h) mm | Thickness (t) mm | Weight kg/m | Colour |

|---|---|---|---|---|

| 500 | 40 | 4.50 | 8.70 | Grey |

Maintenance Free Durability

GRP flooring is built to last, resisting corrosion, moisture and wear without painting or ongoing maintenance.

Fire Rated and Electrically Safe

Each GRP panel is non conductive and Class 2 fire rated, ensuring safe performance in industrial and public environments.

Lightweight Strength You Can Trust

Strong yet easy to handle, GRP flooring panels install quickly and deliver reliable load performance across all applications.

GRP Flooring Sheets and Anti Slip Systems

Engineered Composites supplies GRP flooring sheets and anti slip flooring systems that deliver dependable safety, strength and long term performance. Designed for demanding industrial, marine and public access environments, our flooring products provide a durable, low maintenance alternative to steel, aluminium or timber floors.

High Slip Resistance

Each GRP flooring panel features a hard wearing quartz gritted surface that exceeds HSE standards for wet and dry slip resistance. It provides sure footing in high traffic areas, ramps, bridges and platforms, significantly reducing accident risks.

Fast Installation and Flexible Design

Supplied as pre formed panels or interlocking profiles, our GRP flooring sheets are easy to install and cut to size on site. Lightweight construction simplifies handling, helping contractors save time and reduce labour costs without compromising performance.

Durable and Maintenance Free

Built from corrosion resistant GRP, these flooring systems withstand constant exposure to moisture, salt and chemicals. Once installed, they require no repainting or sealing, providing a long service life and exceptional whole life value.

Deck500 Anti Slip Flooring

For larger industrial and public spaces, our Deck500 anti slip flooring system offers a complete interlocking GRP solution. With tongue and groove connections, high visibility options and a permanent gritted surface, Deck500 ensures safety, strength and compliance in every application. Available from UK stock for fast nationwide delivery, GRP flooring sheets and anti slip sysytems from Engineered Composites offer proven reliability, quick installation and unbeatable long term value.

Need Help Choosing the Right GRP Flooring? Talk to Our Experts!

We’ll help you choose the right solution based on safety, environment & compliance.

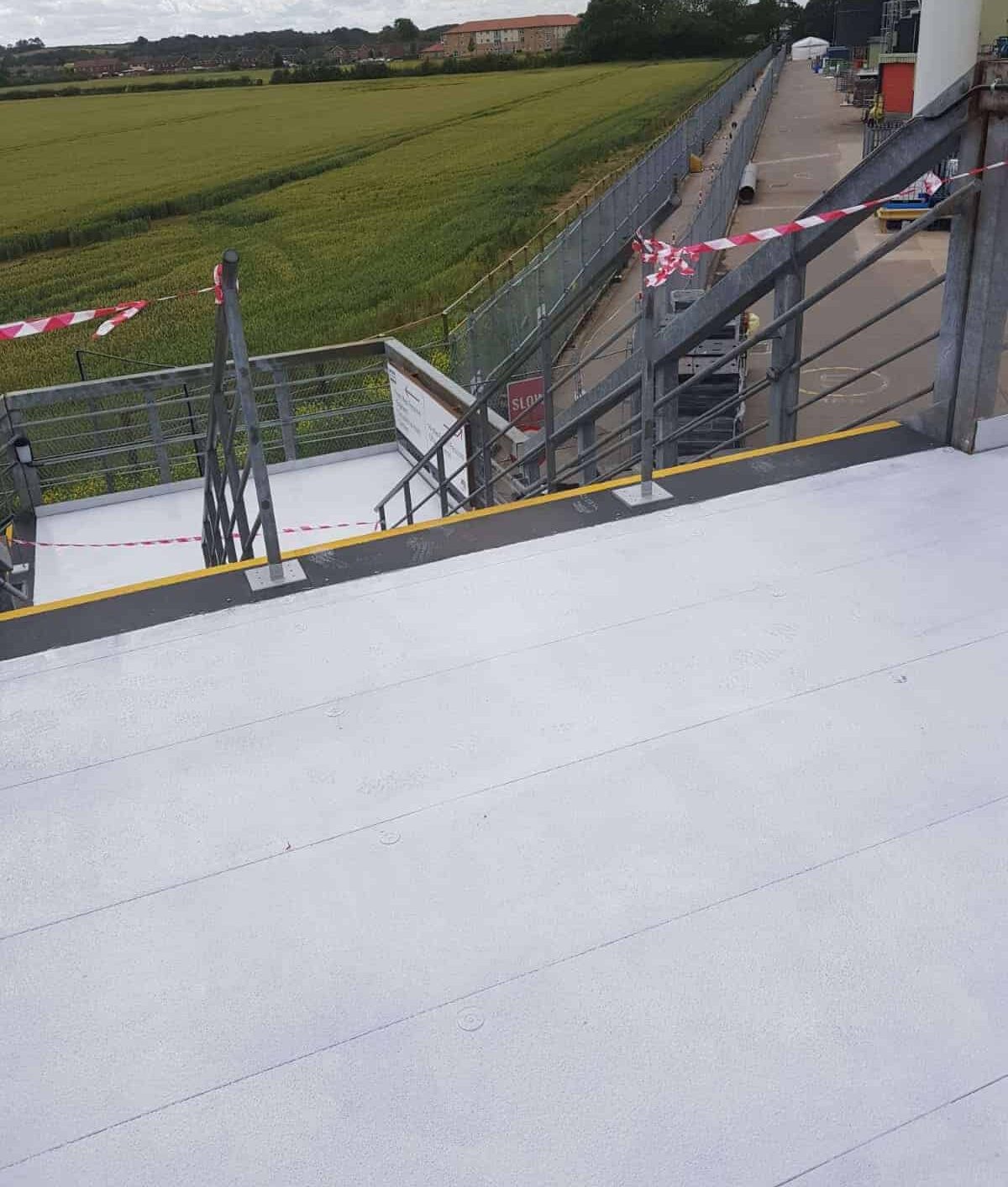

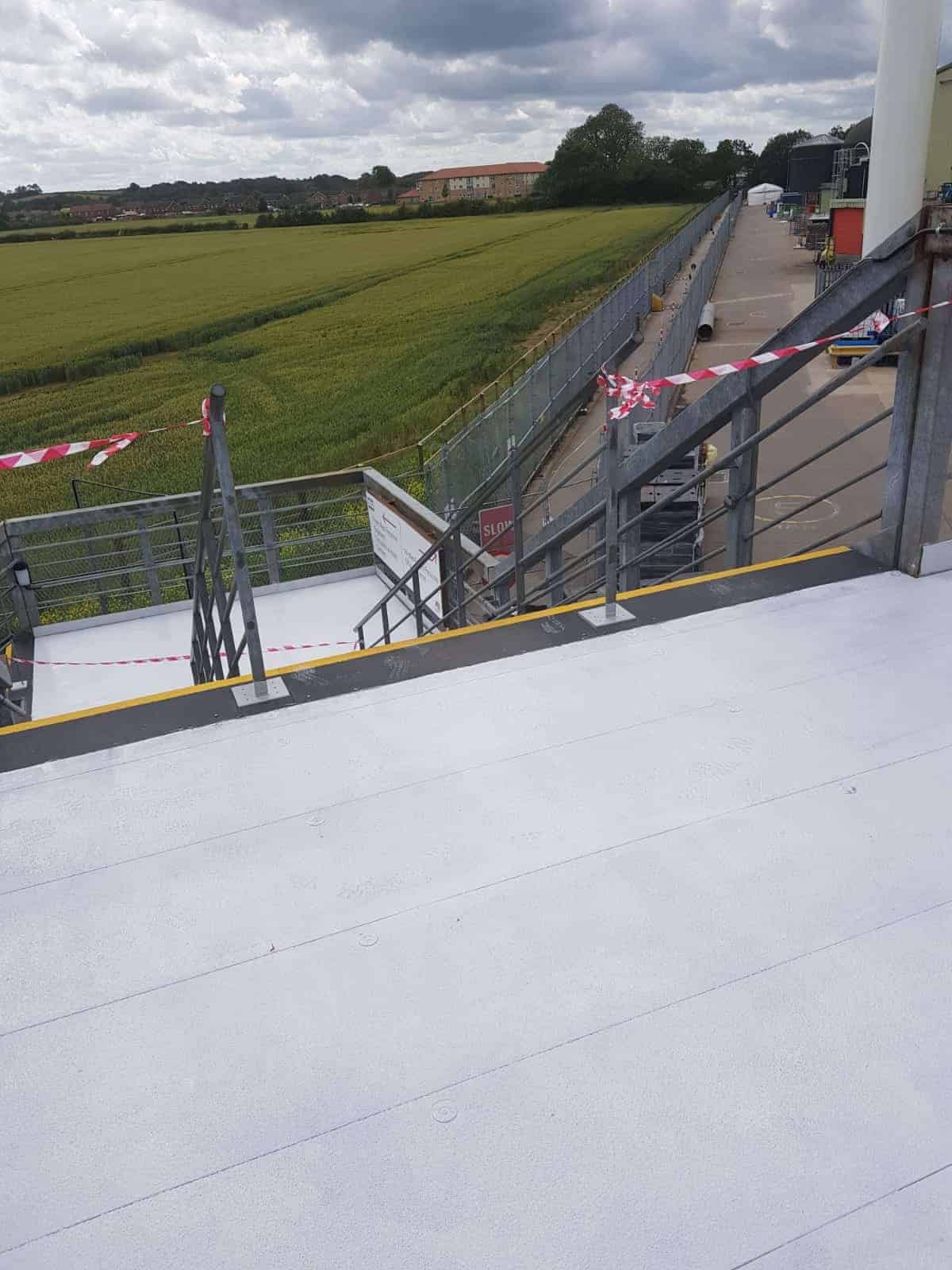

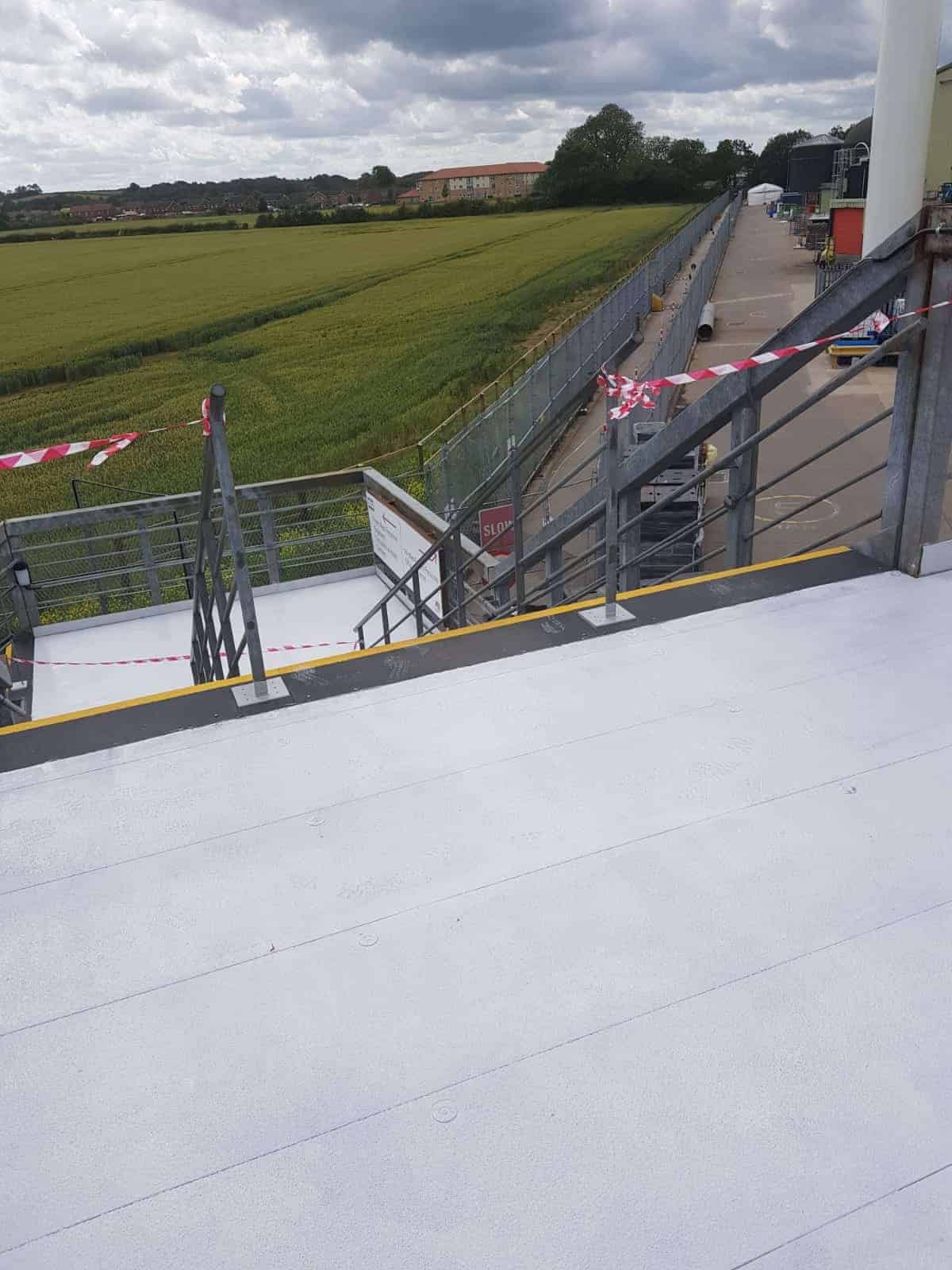

Poole’s Wharf Pedestrian and Cycle Bridge is a vital crossing point for pedestrians and cyclists in the busy harbour side of Bristol. The bridge was in need of refurbishment due to wear and tear, and Engineered Composites was chosen to provide the necessary GRP materials for the project.

Supply of GRP Materials

Engineered Composites supplied Deck 500, Non Slip flat sheet, and Non Slip Decking Strips for the refurbishment of the bridge. These GRP materials are highly durable and have excellent anti-slip properties, making them perfect for high-traffic areas like bridges. The materials were custom-made to fit the specific dimensions of the bridge, ensuring a perfect fit and easy installation.

The Deck 500, Non Slip flat sheet, and Non Slip Decking Strips provided by Engineered Composites offer numerous benefits for the Poole’s Wharf Bridge refurbishment:

Discover More About GRP Flooring

-

Brochure & Tech Specs

View our full specifications instantly! Download Brochure

-

See It in Action

Explore real-world applications! View Case Studies

-

Have Questions? Let's Talk!

Get expert advice today.

Contact Us

What Clients Say About Our Company

With over 39 years of experience, we are a trusted UK supplier of GRP flooring solutions. Our clients rely on us for fast delivery, expert support and durable, low maintenance solutions across every sector.

EXCELLENTTrustindex verifies that the original source of the review is Google. The firm and staff were all excellent, the product was very well finished and all the advice given was very helpful, unfortunately it turned out to be of no use for my application, but this in no way reflects on the company that made an excellent product, I wanted a long tube to put an aerial inside it, fibreglass is normally transparent to radio signals, but something in the make up of the fibreglass tube was totally blocking the radio signals from getting out of the tube, the problem is possibly to do with the colouring agent, the tube I had was grey, darker colours can often cause problems for aerials, possibly if I'd chosen yellow, the other colour offered by the firm it may have worked well, but all this is my problem, not the company that made the tube, the tube is Very well made and nicely finished off, the staff could not have been more helpful, despite my problems this is a Highly Recommended firm. Pete.Posted onTrustindex verifies that the original source of the review is Google. Fantastic company to deal with, they always respond really quickly, have incredibly fast despatch times and provide consistently high quality, innovative GRP products. As a company, we couldn’t ask for more, thanks Engineered Composites.Posted onTrustindex verifies that the original source of the review is Google. Excellent Customer Service. Supplied Composite rebar for our precast units (Macrete Ireland Ltd)Posted onTrustindex verifies that the original source of the review is Google. We've being using Engineered Composites services for over 10 years & long may it continue. Professional at all times & no issues with quality or prices. Great range & availability, would highly recommend them.Posted onTrustindex verifies that the original source of the review is Google. 5-Star service, great company to work with. Make's my life easier with prompt response times, on schedule deliveries and effective communication throughout.Posted onTrustindex verifies that the original source of the review is Google. This is an extremely professional company at the forefront of GRP Composite technology. Always willing to supply First Class advice and bespoke GRP solutions. Highly Recommended

FAQs About GRP Flooring

What is GRP flooring and why is it better than steel or timber?

GRP flooring, or Glass Reinforced Plastic flooring, is a composite system designed to deliver strength, safety, and durability in environments where traditional materials fail. Unlike steel, it will never rust, corrode, or conduct electricity, and unlike timber, it will not warp or rot over time. GRP flooring is also significantly lighter, making it easier to handle and faster to install without the need for specialist equipment.

The panels feature a high-strength anti slip surface for dependable traction and meet BS EN 13706 and BS 4592 performance standards. With zero maintenance requirements and a lifespan exceeding 50 years, GRP flooring offers unbeatable long-term value and is the preferred choice for contractors seeking a reliable, sustainable alternative to conventional materials.

Is GRP flooring safe in wet or oily conditions?

Yes, GRP flooring is engineered specifically to maintain grip and safety under wet, oily, or contaminated conditions. Each panel is manufactured with a gritted quartz surface that exceeds HSE recommendations for slip resistance, offering consistent traction for both indoor and outdoor use. The anti slip finish is bonded during production, ensuring permanent protection that will not peel or wear away.

This makes GRP flooring ideal for industrial walkways, marine platforms, food processing plants, and areas prone to moisture or spills. Tested to BS 7976, it provides reliable safety performance even after years of heavy use. The surface design reduces accident risks while delivering a professional, clean appearance that remains effective throughout the life of the installation.

How long does GRP flooring last?

GRP flooring is designed for an exceptionally long service life, typically exceeding 50 years with no loss of strength or surface performance. The composite structure is resistant to corrosion, impact, moisture, and chemicals, allowing it to withstand continuous use in harsh environments such as factories, marine docks, or wastewater plants. Unlike metal or wood, GRP flooring requires no protective coatings or repainting, significantly reducing lifetime maintenance costs.

The panels maintain their colour, texture, and slip resistance in both indoor and outdoor conditions. Engineered Composites supplies only high-grade GRP flooring tested to meet British and European standards, giving clients long-term reliability and exceptional whole-life value from every installation.

Does GRP flooring require maintenance or repainting?

No. One of the major advantages of GRP flooring is that it is completely maintenance free. The panels are made using UV-stable resin systems that prevent fading, and their corrosion-resistant structure ensures the material will never rust, rot, or degrade. Unlike steel or timber flooring, GRP does not require painting, galvanising, or chemical treatment to preserve performance.

Occasional cleaning with mild detergent is all that’s needed to maintain appearance and safety. This “fit-and-forget” benefit makes GRP flooring particularly attractive for industrial and public infrastructure projects where downtime is costly. Engineered Composites’ GRP flooring systems are designed for minimal upkeep, delivering lasting performance and outstanding long-term value.

What load capacities and panel options are available?

GRP flooring is available in multiple sizes and configurations to suit a wide range of applications. Standard panels are typically 40 mm thick with load capacities of up to 5 kN/m², depending on span and layout. Engineered Composites can also supply bespoke panel sizes and thicknesses to meet project-specific load or deflection requirements. Each panel is manufactured using high-strength GRP profiles compliant with BS EN 13706 and BS 4592 standards.

The flooring is tested for wind, impact, and live load resistance to guarantee consistent strength and performance. Optional colours, finishes, and nosing can be specified to improve visibility, safety, and compliance with workplace standards. Every order is backed by detailed technical documentation and expert design support from our in-house engineering team.

Is GRP flooring non conductive and fire resistant?

Yes. GRP flooring is fully non conductive, making it completely safe for use around electrical equipment, substations, and high-voltage environments. Unlike metal, it will not transmit electrical current or spark under impact. The material is also manufactured with fire retardant resins and achieves a Class 2 rating under BS 476 and ASTM E84 testing standards.

This combination of fire safety and electrical insulation makes GRP flooring ideal for industrial, marine, and public installations where safety compliance is essential. Each panel is designed to deliver lasting performance under extreme conditions, maintaining structural integrity and surface grip even when exposed to high temperatures or heavy traffic.

Can GRP flooring be supplied from stock for fast delivery?

Yes. Engineered Composites holds extensive UK stock of GRP flooring panels, fixings, and accessories for immediate dispatch. Standard panel sizes and colours are available for same-week delivery nationwide. This stock availability allows contractors to complete projects on time, avoiding long lead times associated with made-to-order metal or timber systems.

Panels can also be supplied cut to size or as modular sections for quick on-site installation. With a dedicated logistics network and fast turnaround on all orders, Engineered Composites provides reliable supply, ensuring your GRP flooring is on site when you need it.

Can GRP flooring be cut or modified on site?

Yes. GRP flooring panels can be easily cut or trimmed on site using standard power tools fitted with fine-tooth blades. The lightweight design makes handling simple and allows for fast adjustment without specialist equipment. This flexibility is ideal for projects that require precise fitting around pipework, platforms, or uneven surfaces.

Unlike metal flooring, GRP does not produce sparks or require hot works permits during modification, making it safer for confined or live environments. Engineered Composites provides full installation guidance and technical support to ensure panels are fitted correctly and securely for maximum lifespan and safety.