GRP Box Sections

Strong, lightweight, and non-conductive GRP profiles perfect for structural frameworks, handrails, platforms, and more.

Engineered Composites supplies high-performance GRP Box Sections manufactured using pultruded Glass Reinforced Plastic. These hollow box profiles are engineered for strength, low weight, and outstanding durability in harsh and demanding environments.

Ideal as a replacement for timber or steel, GRP box sections resist rust, corrosion, and electrical conductivity – making them a safe, long-lasting choice for structural framing, rooftop applications, handrail posts, or modular installations.

GRP Box Sections

Trusted GRP Box Section Solutions

Engineered to BS EN13706 standards, our GRP Box Sections combine structural integrity with ease of installation. Their closed cross-sectional shape offers high torsional stiffness and strength, while the composite material ensures long-term performance without rust, rot, or chemical degradation.

Whether you’re building fencing posts, machine guards, structural frames, or cross beams, GRP Box Sections provide reliable, low-maintenance solutions. They’re also fire retardant to Class 2 and 100% non-conductive – ideal for electrically sensitive or high-risk environments.

-

GRP Box Section Specifications

-

Standards & Benefits

Profile Sizes: 25mm – 150mm (square and rectangular)

Wall Thickness: 3mm to 10mm

Standard Length: 6 metres (bespoke options available)

Material: Isophthalic resin + E-glass fibre composite

Colours: Grey (standard), Yellow (select profiles)

Fire Rating: Class 2 (fire retardant)

Conductivity: Electrically non-conductive, non-sparking

Weight: Up to 50% lighter than steel

Standards: Compliant with BS EN13706 and ISO9001 supplier certification

Lightweight, corrosion-free and maintenance-free

Non-conductive and weather-resistant

Suitable for rooftop installations and clean zones

No painting, priming, or anti-rust treatment required

Long service life with minimal lifecycle cost

GRP box section Case Study

Objectives

The use of Glass Reinforced Polymer (GRP) composite materials is of growing interest to the Research team at Kingston University. The expert team believe the unique properties of Pultruded GFRP, such as its high weight to strength ratio, make it an ideal construction material in a world that demands efficiency and environmentally friendly materials.

Challenges

- Modern architecture is embracing minimal designs.

- Lighter and more efficient materials needed for construction.

- Life Span and durability issues with current materials.

Solution

Dr. Behrouz Zafari Kingston University

Corrosion & Weather Resistant

No rust, rot, or degradation over time

Non-Conductive & Fire Retardant

Safe for electrical and industrial sites

Lightweight & High Strength

Easy to install with exceptional durability

Why Choose GRP Box Sections?

GRP Box Sections deliver superior performance in high-risk or industrial environments where steel or timber would corrode, rot, or conduct electricity. Their modular format and cut-to-length flexibility make them perfect for bespoke structural applications and quick, safe installations.

High Strength-To-Weight Ratio

Robust and rigid while being significantly lighter than metal.

Zero Corrosion Or Rot

Long-lasting performance in marine or chemical environments.

Non-Conductive Safety

Safe for use near live electrical systems and substations.

Fire Retardant Class 2

Certified protection in elevated temperature environments.

Fast Installation, Low Maintenance

Easy to cut, drill and fit on-site with no welding required.

Customisable Format

Choose your size, colour, wall thickness, and finish.

Not Sure Which GRP Box Section You Need? Speak With Our Experts Today.

We help you choose the perfect size, configuration, and spec for your project.

Applications & Environments

Structural Framing & Bracing

Commonly used in platforms, walkways, and roofing trusses.

Handrail & Barrier Posts

Durable, non-conductive posts for safety barriers and guardrails.

Modular Walkways & Platforms

Lightweight GRP support structures for access and platforms.

Non-Conductive Fencing

Used for electric-safe perimeter fencing and posts.

Machine Guards & Clean Rooms

Safe in hygienic or spark-sensitive areas.

Transport & Rail Infrastructure

Corrosion-resistant framing for depots, platforms, and tunnels.

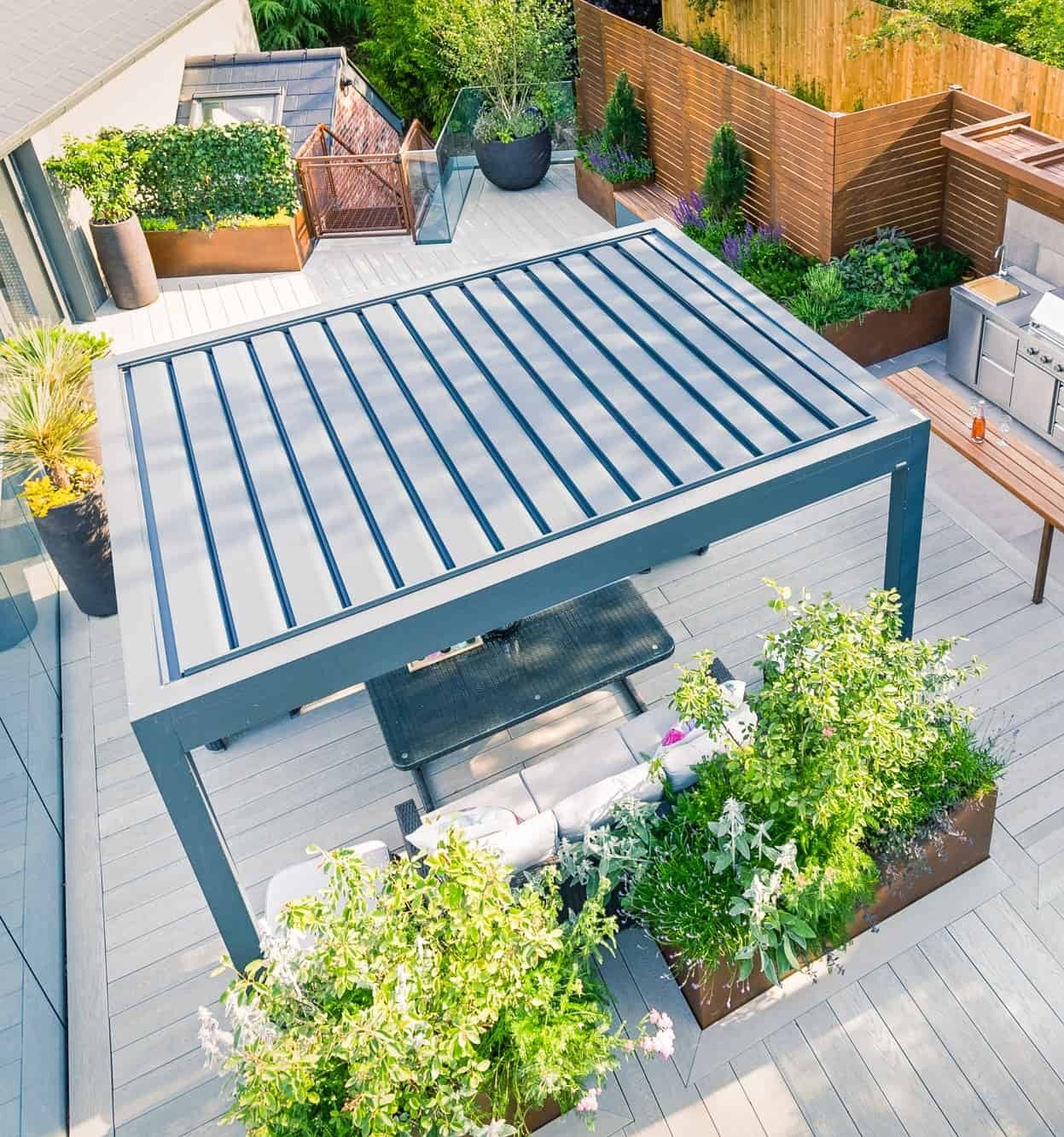

Rooftop Systems

Ideal for weight-sensitive installations on commercial roofs.

Discover More About GRP Box Sections

-

Brochure & Tech Specs

View our full specifications instantly! Download Brochure

-

See It in Action

Explore real-world applications! View Case Studies

-

Have Questions? Let's Talk!

Get expert advice today.

Contact Us

What Clients Say About Our Company

EXCELLENTTrustindex verifies that the original source of the review is Google. The firm and staff were all excellent, the product was very well finished and all the advice given was very helpful, unfortunately it turned out to be of no use for my application, but this in no way reflects on the company that made an excellent product, I wanted a long tube to put an aerial inside it, fibreglass is normally transparent to radio signals, but something in the make up of the fibreglass tube was totally blocking the radio signals from getting out of the tube, the problem is possibly to do with the colouring agent, the tube I had was grey, darker colours can often cause problems for aerials, possibly if I'd chosen yellow, the other colour offered by the firm it may have worked well, but all this is my problem, not the company that made the tube, the tube is Very well made and nicely finished off, the staff could not have been more helpful, despite my problems this is a Highly Recommended firm. Pete.Trustindex verifies that the original source of the review is Google. Fantastic company to deal with, they always respond really quickly, have incredibly fast despatch times and provide consistently high quality, innovative GRP products. As a company, we couldn’t ask for more, thanks Engineered Composites.Trustindex verifies that the original source of the review is Google. Excellent Customer Service. Supplied Composite rebar for our precast units (Macrete Ireland Ltd)Trustindex verifies that the original source of the review is Google. We've being using Engineered Composites services for over 10 years & long may it continue. Professional at all times & no issues with quality or prices. Great range & availability, would highly recommend them.Trustindex verifies that the original source of the review is Google. 5-Star service, great company to work with. Make's my life easier with prompt response times, on schedule deliveries and effective communication throughout.Trustindex verifies that the original source of the review is Google. This is an extremely professional company at the forefront of GRP Composite technology. Always willing to supply First Class advice and bespoke GRP solutions. Highly Recommended

FAQs About GRP Box Sections

GRP Box Sections are primarily used in structural applications where durability, corrosion resistance, and non-conductivity are essential. Common uses include framing, support posts, handrails, roof trusses, machine guards, and walkways. Their hollow profile provides excellent torsional strength, making them ideal for both load-bearing and safety-critical installations in industrial, marine, or electrical settings.

Yes, GRP Box Sections are a reliable alternative to steel or timber. Unlike traditional materials, they do not rust, rot, or conduct electricity. They are significantly lighter, which makes them easier to handle and install. GRP also requires no painting or coating, reducing both initial and lifecycle maintenance costs over time.

Absolutely. All GRP Box Sections from Engineered Composites are manufactured to BS EN13706 standards for pultruded profiles. Additionally, we are an ISO9001-accredited supplier, ensuring consistent quality and traceability. These profiles are also available with fire-retardant properties, meeting Class 2 standards, making them suitable for use in regulated sectors such as rail, chemical, and electrical.

Our GRP Box Sections are available in square and rectangular profiles ranging from 25mm to 150mm. Wall thicknesses typically range between 3mm and 10mm, depending on load and application requirements. All box sections are supplied in 6-metre lengths as standard, with custom cutting available for project-specific lengths and configurations.

Yes. GRP Box Sections are engineered for use in harsh outdoor and chemical environments. They are resistant to corrosion, UV rays, salt spray, and aggressive chemicals such as acids and alkalis. This makes them ideal for marine, coastal, utility, and wastewater treatment applications where traditional materials may degrade over time.

GRP Box Sections are easy to cut, drill, and fix using standard hand tools, with no need for welding or specialised equipment. They can be bonded, bolted, or surface-mounted to suit your application. Their lightweight nature reduces manual handling risks, and their non-conductive properties make them safe to work with near electricity.

No. One of the key benefits of GRP Box Sections is their low-maintenance nature. Unlike steel or timber, they do not require painting, anti-corrosion treatments, or chemical coatings. Once installed, they provide reliable performance for decades, even in extreme conditions, offering an excellent return on investment with reduced lifetime costs.

In many cases, Engineered Composites are able to provide next-day delivery for GRP Box Sections and alternate GRP products. If you have an urgent order, we urge you to get in touch with us immediately so we can arrange for you. If we can’t arrange for next-day delivery due to high demand, we will make sure to inform you.